Oil pumps

contributed by Ian Simpson

What you need to know....

The 5GTT C1J engine has a different oil pump to the other C1J engines.

As far as I can tell it moves a greater volume.

This means that a suitable pressure can be maintained when the C1J has a turbo attached to it.

Some tuning companies were selling the non turbo type of oil pump and plenty of people have complained that their engines crank and turbo bearings packed up shortly after fitting this claimed 'suitable' but evidently unsuitable replacement pump.

"That was the pump I bought from someone Tuning that they were advertising as an "uprated" pump for the GT Turbo, the big end went a few months after fitting." Is heard from time to time.

Someone did some comparisons and found it took longer for the Campus pump to get oil to the turbo than for the GT turbo pump when viewing through a transparent pipe, or something like that. I seem to recall that I've heard it said that it takes the Campus pump longer to make the oil pressure from starting the engine.

Photos and pictures can be found on the site.

Here's a link to a thread.

They don`t have the part number (7701635029) stamped on the pump.

Turbo pump has a split pin.

Campus pump doesn`t have a split pin.

Thanks to Lewis Cole for this part:

For the C1J series engine Renault state that the oil pump should meet the following minimum pressure in Bars @ 80°C:

naturally aspirated

idling speed 0.7

4000 RPM 3.5

turbo charged

idling speed 1.3

4000 RPM 3.2

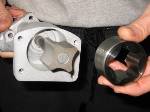

The naturally aspirated C1J engine uses a twin cog 'gear' type oil pump. This has proved unsuccessful as a replacement oil pump for the C1J Turbo engines. The turbocharged C1J engine uses a single large eccentric rotor type pump.

Due to the high mileages some of our cars are reaching the oil pumps are starting to wear causing the oil pressure at the given rpm’s to drop below specification.

Fitting a gear type pump as fitted to the N/A C1J is not an option. Although the pressures produced are suitable the flow rate of the gear pump is less than that of the rotor pump. This causes problems due the increased oil volume requirement of the turbocharged car due to the oil cooler, turbocharger and associated oil feed/return pipes. And mainly because the turbo is in parallel with the engines other bearings and therefore returns extra oil volume through it to the sump, so needing the extra volume from the pump to prevent the engines oil pressure lowering too much. Also the turbo itself needs a high pressure to be maintained to prevent wear. Low oil pressure being probably the main reason for turbo bearing wear (maybe next to oil contamination)

To achieve the correct oil pressures it leaves us with two options:

1: Buying a new pump from Renault is still possible although stocks are getting less, this is reflected in the price of a new oil pump from Renault which recently was around £600+vat

2: Buying new pump innards. Mecaparts sell an oil pump repair kit MP0482 for €62 (≈£60 delivered) which is the shaft with inner 'cog' and the surrounding 'cog'. BBPT 'oil pump refurbishment kit' for £70.50 inc vat which is just the one part.

Although your pressure may not be within the given specification this may be down to other factors. Therefore the oil pump needs to be disassembled to check dimensions of the rotor clearances.

-The oil pump is mounted to the underside of the engine block inside the sump. It is driven by the camshaft via the gear that also turns the distributor.

-The sump is removed by unscrewing the 14 M6 bolts, with a 10mm socket and ratchet with extension and levering it away from the Thixo silicon gasket.

-The oil pump itself is secured to the engine block by three 5mm Allen key bolts, undo these taking care not to loose the star washers.

-With the oil pump separated from the block it is necessary to separate the oil pump filter body from the rotor housing body, this is done by unscrewing a four more 5mm Allen key bolts with star washers.

-With the oil pump housing separated it is possible to remove the two parts of the rotor, do this and wipe all the internal surfaces of any oil.

-With all oil cleaned the two parts are re-fitted and measurements of rotor clearance can be taken. See Picture 2;

The clearance allowed for A are: min 0.04mm and max 0.29mm.

-For the second measurement turn the rotor until it matches the same position in picture 3, then take measurements at both B.

Clearances allowed for B are: min 0.02mm and max 0.14mm

-If the wear exceeds either of these tolerances the pump must be replaced or new internals fitted.

Before final reassembly make sure you first apply plenty of engine oil to all surfaces and maybe fill pump with oil, or better pack the pump with graphogen so it initially sucks up the oil better. After the new part(s) are in, the pump might be little harder to turn by hand.

Does an uprated (high flow/high pressure) oil pump for the c1j exist?

technically there is one.....

This link shows a fresh casting of a new oil pump that has a deeper body than standard.

http://keops-racing.skyrock.com/17.html

http://keops-racing.skyrock.com/

http://keos-racing.skyrock.com/

Ian S RTOC Profile

5GTT oil pump internals

See the wear on the splines

5GTT pump on left and 'Campus' pump on right

5GTT oil Pump

5GTT oil pump

Reply With Quote

Reply With Quote