Hi Alex, massive apology!

I haven't forgotten about this, I was asked to make one of these up, and that order turned into 10...and it has taken up all of my time over the last 6 weeks, that I wasn't expecting!

It's taken a while to sort out having the downpipe flange cut to make to suit your T2 exhaust housing but the measurements I have for the holes centres on my housing are different to the drawings my laser cutting has for these, but I thats all sorted now. I have made another complete downpipe for you with the flange tweaked over 5mm so I am just waiting for the new flange to arrive now. I'm finally back on track now.

Hi Matty, good to hear from you. No bother at all - glad you're still progressing with thisThat manifold looks awesome, maybe that can be your next RTOC 'project' once the downpipes are sorted

My car is just sitting there is various bits at the moment so I'm happy to continue with the trial fitments when you're ready

If the down pipes are made, how much are you looking at selling them for? Our friends on the other side are asking £300 each which I think is too expensive. How much can you do a batch for Matty?

Im hoping to do some manifolds too, I've got a flow bench 50% made which I'd like to get running so I can do some off car trials on the parts ive made, as it would be nice to give some performance figures on parts. But downpipes first, and full systems. Things have quietened down now race season is over, so I can get cracking on with this.

Matt - Ive gone back to the original design now, due to the clearance on the water pipes as mentioned above, so I can do these for £240 if I can do a batch of them.

That's fine mate.

I know it's a while ago since we had any Big Jim pipes, and I'm not trying be negative or pick holes, just saying that's all, but IIRC we were SELLING those downpipes from the shop for £150. I bought a batch of 10 from him. It took him 1 hour to make each one.

materials have gone up alot since then these sound good for £240 ish with excellent build quality by the look of it, if it wss me doing it there would be loads of bird sh1t around lol, at the end of the day ian youll get the club money back once sold which i think they will sell very quick, but only prob a max order of maybe 5 a time

I have to admit I had the first TR custom downpipe and it had a lot more work go into than the ones they are currently selling and it had all the lobster effect done to it and back purged it did look really nice in the flesh. I bought it off them at cost so I was told for £210.00 that included courier cost's. I was advised that they used a BMS downpipe to make the jig up.

Pic's attached of the one I had, not saying the RTOC one needs to be lobster backed but would be nice to have the plate on with RTOC printed on it :-)

Going in line with pricing, even back in 2011 this message was done from Big Jim

Hi there. Haven't got any turbo exit flanges left. Could buy one and put a downpipe together for you but it would have to be a bit extra.

The price of everything has gone up since I started doing them for £150 so would have to say more like £190 and this would be the VERY last one.

If you're interested let me know.

That's about 12 weld 'rings' on there so a lot of labour time in measuring, cutting, assembling, tacking pieces together and welding.

Jim did it in two to three 'Easy Bends'. He had laser cut flanges made for him in batches of 10 sets.

If the materials were £15 for one set of flanges and £25 for the rest, so £40. If the materials price has risen by as much as 25% then that's £50.

I don't have any actual numbers but perhaps some could add them here?

As far as selling fast I can't predict but IIRC we had two batches from Jim, 20 pipes, and was a couple of years to sell them. How many 5GTT still rolling don't already have one?

Just seen you post Dale, I think he was making about £100 per pipe for an hours work, I really don't know why he didn't want to do any more at that profit margin. That cost increase there would be due to having to make one pair of flanges himself. And possibly the postage to him for one set of pipes.

But were talking about sets of 10 now, so economy of scale.

Either way, Jims not doing them now. If they cost RTOC £240 and the shop can make it money back once postage and PayPal, etc, is added and actually sell them for £300 or so then RTOC should meet the demand from those affluent people.

its cool whatever ian just be a bit of class to have these in the club shop again, id suggest only 5/10 at a time as you say theres not that many 5s left but a deffo plus in lots of respects for the club, I agree to with james a rtoc metal tag plate is a must if its possible matty

remember too ted said he may have some on the way

Theres much more to consider that flange and pipe costs.

Flanges

Pipes

Argon gas + back purge gas

Filler rod

Tungstens

Labour intensive for good fit up before welding

Gas isn't cheap and price of stainless isn't that cheap anymore.

Building a stock of 10, these days you'll probably sell 1-2 each month in reality

Lobster backing really isn't good, the whole is for the downpipes to flow well, and lobster backing just creates a series of ripples in the pipes.

RTOC name plates are simple enough to do, but then is that another unnecessary expensive if people want to keep the costs down?

I really can't see how someone could make one in an hour, it takes a few hours making the first bend a good fit in the flange and making the fillet piece a nice fit. Everything is tacked, the first elbow pieces tidied up so when its welded the is no overlap on the joins, and pipes are rounded up at the joins, so there is no step in the pipes, the flange join is also welded on both sides, both ends, When you add the cost of 3 flanges, 2 bends, lambda boss, gas, filler rod and general consumables used it soon adds up, and back purging uses more gas especially on larger dia pipework. As I am set up as a business I also have tax to pay on everything I make. Its very difficult to get prices down when ordering small quantities of flanges, the price difference between 1 flange or 10 is about £1 a flange, so they near enough cost the same to make in materials, you might save an hour or so per exhaust doing them in a batch as you can do the as a production run.

If you would like to supply them in the club shop, then I am more than happy to discuss pricing and quantities, but until I get a small batch done its difficult to say exactly how much quicker making a batch of them will be.

I'm also not convinced it only took him an hour to make one. I've been trialing Matts downpipes and have seen the quailty of the welds and pipe work etc. Once we have the final article I would agree with Mick and stick maybe 5 in the club shop and see how we go from there. As long as Matt is good with that.

Thats fine with me. I will look into getting the rear section of the 2.5" systems made up. The front section is straight forward, so if I can get the rear section made to fit an existing side exit setup first, the front part can be made after, that will save some time getting the ball rolling on these.

I have looked into doing the strut braces too, does anyone know what diameter the main bar is? It looks to be about 42mm from photos I have seen.

Yeah putting in the club shop would be ideal, though complete exhaust systems wont be for me due to size, whereas the downpipes can be sent by royal mail as I do all the rest of the stuff.

Yeah, Jim was stocking the downpipes and posting direct to the customer for us.

If I make up a 10mm² mains lead it takes me about 3 hours.

When I was doing them often and making batches I got the time down to about 1 hour.

I have just put an 'interested' post on facebook to see what feedback we get from the club members. Up to know all positive and I think this will be a great product especially if exhausts can be offered also.

pressures on Matty!

I'll be sending off the rear bends next week to be copied off the original system. What tips would people generally want on the back box? Outwards rolled, plain etc...? I guess most will want just a single silencer system and not want the mid silencer?

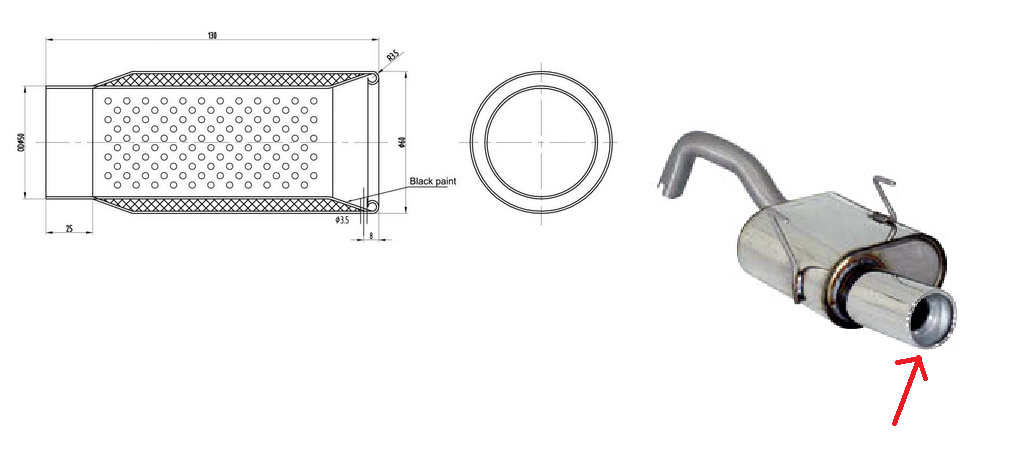

Silenced tail pipe. Ie, lined with perforated tube surrounded with wadding. My Fiat Janspeed has that as did the Blue Flame 'Mongoose' for the 5. It can, or does, take some nasty harshness of the sound. IMO, the Mongoose was the best sounding exhaust I heard on a 5, more like a musical instrument, trombone at lower revs, trumpet at higher.

Won't you need to take the bend higher than an original 'pea shooter' exhaust to allow for the wider bore? And be more precise with the routing so it doesn't knock? It can be a challenge to have it clear the cross beam, double so on a lowered 5GTT.

The 2.25" Mongoose exhaust I had sounded lovely but only once I'd ripped out the small silencing element that was inside the actual tailpipe!

The tailpipe was inwardly rolled around an end piece, once I'd ground the rolled section off I was able to stick the handle of a hammer up the perforated inner and wiggle it around until the welds broke at the exit of the back box. Then it sounded great rather than being an OE-like stainless replacement.

It was somewhere between the sappy Magnex and a side-exit. Perfect for my sensibilities at the time.

Edit - a bit like this crappy contraption:

If it was my money, I'd want a 2.5 or 3" unsilenced tailpipe like the scorpion systems

I think the old scorpion was the dogs. Also the mongoose a good second. Mongoose being the better made.

If I was after a rear exit I'd just want 2.5" all the way through including the tailpipe, nothing fancy, just purposeful. A good option for the tailpipe would be like the old Devil design.

Did you ever hear it from outside the car with someone else driving? From inside the car you can't really hear it.

I replaced it with 2 1/2 inch side exit. Too loud, made my ears suffer. Still have it but had the car remained working I expect I would have change to the 2 1/2 rear exit I also have. (straight through, obviously, Magnex had a restrictor in all but the very early version and Scorpion had a tiny bore silencer, maybe 1 1/2 inch. With a 4 inch tail pipe!!

I want a battery car now as I'm sick of the damn noise.

Ian do you still have your five?

Well I had my 5 MOT'd today, so while it was on the ramps I had a good look at the exhaust with it on its wheels. I can see the issue with the beam, but there is plenty of room above. I've had a look at the standard system I have in the workshop and I think I've sorted where an improvement can be made to gain more clearance on the beam.

I'll order some bends up and piece one together, then I'll get them CNC bent as a one piece rear section.

I was interested to see what system I had fitted as it is louder than standard but it has middle box too...turns out it has no back box, just a tailpipe welded onto the 1 3/4 pipe

Looks like I'll be putting my name on the list for a full system.

This is my back box...

I do. But I can't afford to get it working. Even though I have most of the parts, I can't afford the extra insurance. I'd have to run the Fiat with the 5 as a classic to get a good price, but with extra tax, etc, it still maybe £500 to £1000 a year I don't have. Plus I'd need to have a fair bit of body work done first and get an engine.

Matt, have a think if a 3" is possible too.

3" should be possible, but the rear beam may cause an issue. A 3" downpipe would almost be easier with regards to the flange join.

Thanks for putting the word out on FB.

This might be a good excuse for me to fit my T2/25 turbo and get a full 2.5" system on mine.

Well plenty of interest on RTOC Facebook. People would like full exhausts too!

Any timescales on the dp matty?

Flanges are all cut for the T2 and T25 and being sent today, so I can the downpipe finished this week, and I'll trial fit it on my car this weekend, so I can make sure the jig is correct. As I've only got a standard 1 3/4 system, I'll send it over to Alex to fit on his so it can be properly bolted up to the system. If its all good, I can get on with them straight away. The full system bends are being CNC bent later this week. I'm lowering my car 35mm this weekend, so I can make sure there is enough clearance on the beam with a lower drop. So its all go!

No price for the systems yet, one of the places I use for CNC bends said they couldn't make the 'S' section in one piece. So I've measured the bend angles to order the bends up individually and once I get it all welded together and it all fits, I can get a price from another supplier. They are usually more expensive for one off due to set up time, but if I can get a batch done together it will bring the costs down.

I was basically looking at doing a standard system from the downpipe back to the beam, then within reason, people can choose whether they would like a silencer fitted and what size tips etc...it would be nice to make them all the same, but it shouldn't be too much of an issue swapping the back section as this will be seperate from the mid section.

Righty I've had a look into the exhaust fitment of the both downpipes I have made.

The first one has much more clearance on the heater pipes, but I still might be able to get the second design to work, which will be better a flowing elbow.

Here's the pics, the first design. Plenty of clearance all round.

Second design. (Before jig change) it needs a slight tilt change on the flange, but the lower section looks near enough spot on (I'm using a 1 3/4 mid section at the moment). There is about 10mm clearance on the heater hoses, but I might be able to get this to 20mm in the same design, with a shorter cone and less of an angle on the whole pipe. I guess most people ditch the heat shield bracket at the back where the downpipe runs? and do away with the support bracket on the box where it joins the mid section? A 2.5" fits through the bracket, but the holes in the bracket put the mount holes for the exhaust flange into the flared section of the centre section part....if that makes sense?

Looks awesome matey. I guess some of the original brackets have to go in a quest for smooth flow and size.

That's not a heat shield bracket, it's job is to hold the weight, and keep the position, of the exhaust and turbo. Otherwise the whole lot is hanging off the manifold and wobbling around.

That some people don't fit them might be why their exhaust housings crack and is perhaps the cause of the manifold gaskets going at the turbo end.

I had the brackets and a T28 and the Ktec 2 1/2 inch downpipe and side exit and it all fitted OK. Except I made my own stainless bolts arrangement for the flexible coupling.